Understanding EV batteries

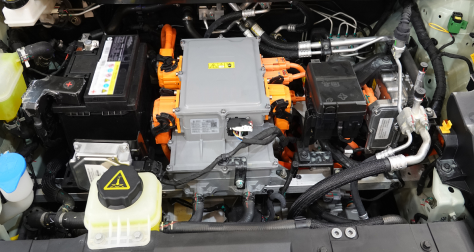

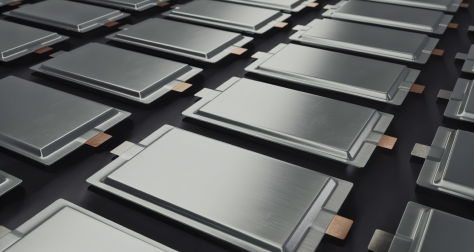

Battery composition

Electric vehicle (EV) batteries consist of various components, each playing a crucial role in powering the vehicle. These include the anode, cathode, connectors, control circuits, cells, modules and terminals. The anode and cathode facilitate the movement of electrons during charge and discharge cycles, while connectors and terminals establish electrical connections within the battery. Control circuits manage the battery's performance, ensuring efficient energy transfer. Cells form the basic building blocks, combined into modules to create the overall battery pack.

Battery sizing

Choosing the right size for an EV battery involves considering factors such as energy storage requirements and desired driving range. The unit of energy storage, kilowatt-hours (kWh), is used to assess a battery's capacity and potential range. Larger batteries offer extended ranges but may increase weight and cost. Selecting an optimal battery size is crucial for meeting the specific needs of fleet operators, property owners and workplace charging stakeholders, balancing range requirements with cost considerations.

Temperature impacts on batteries

Battery performance is significantly affected by temperature variations. Changes in temperature alter battery chemistry, impacting factors like range, charging times and overall longevity. Proper thermal management systems are essential to mitigate these effects, ensuring optimal performance and longevity. Understanding these temperature dynamics is vital for stakeholders involved in installing and managing EV charging infrastructure, as it influences the overall efficiency and reliability of the charging systems.

Cost recovery (replacement costs)

Considering the long-term financial implications of battery replacement is essential for stakeholders investing in EV technology. Battery resale value, repurposing for grid backup storage or on-site power backup can aid in cost recovery. Exploring resale markets and downcycling batteries for secondary applications can offset replacement costs. However, stakeholders must also be aware of the initial investment in purchasing new batteries as part of long-term maintenance. Evaluating these aspects is critical for fleet operators, property owners and charging operators to ensure the economic viability of their EV investments.

Battery afterlife

The afterlife of EV batteries poses both environmental and economic challenges. Understanding battery recycling, resale and the environmental impacts is crucial. Lithium-ion batteries, prevalent in EVs, contain materials like transition metal oxides, aluminum, copper and harmful electrolytes. Improper disposal poses threats to human health and the environment. Initiatives like recycling, repurposing and developing advanced recycling infrastructure are essential for minimizing ecological damage. Stakeholders must actively engage in responsible battery management to align with global sustainability goals and ensure a circular loop for critical battery materials.